on

Allow us to introduce ourselves

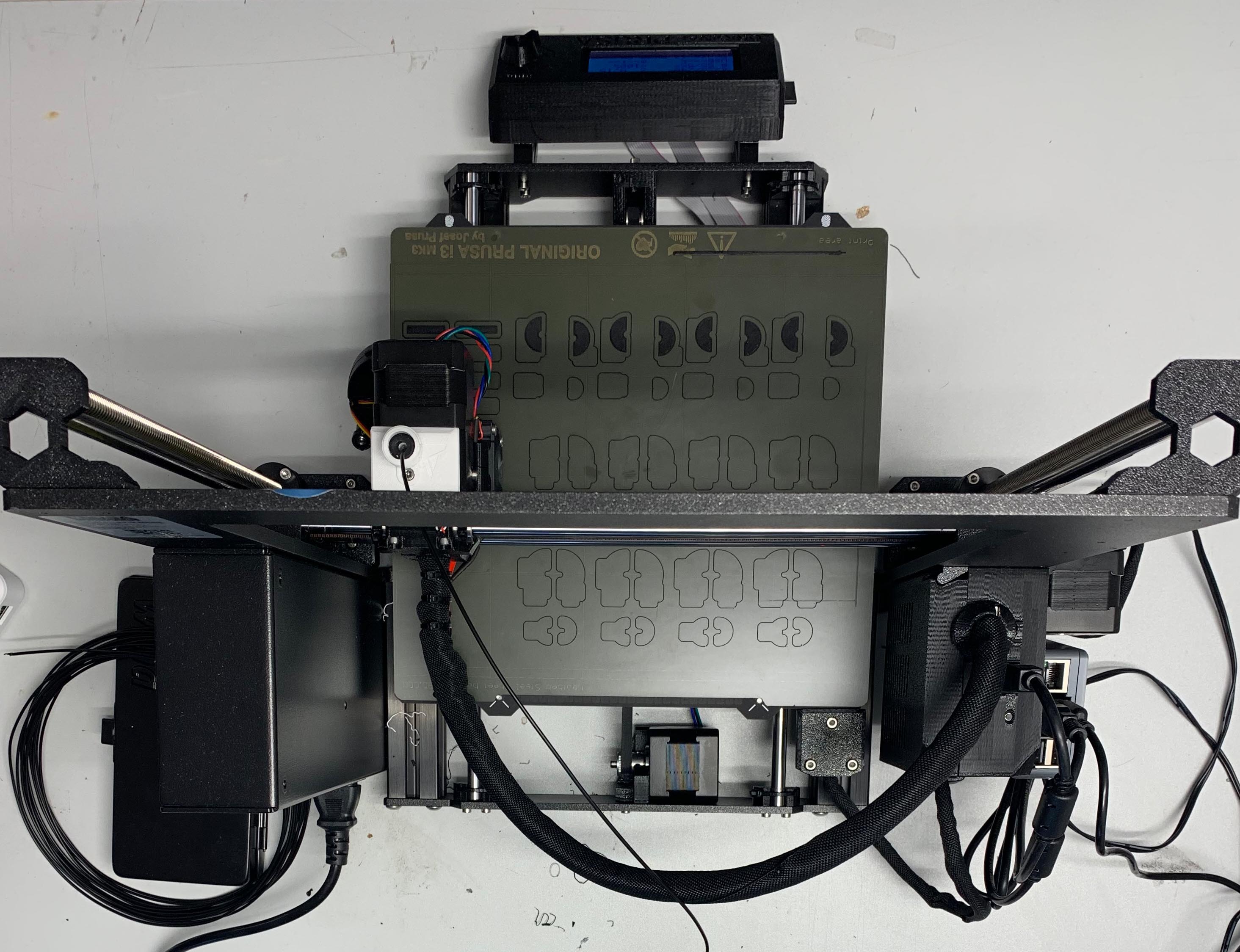

One of our 3d printers building the casing for Jupyter, our voltage sensor

One of our 3d printers building the casing for Jupyter, our voltage sensor

I’m sure anybody who just started their own blog or remembers their humble beginnings can relate to this sheer urge of creativity twitching through your fingertips; ready to write down hundreds of pages - but something’s missing: That very sentence followed by so many others, marking your first step into this new world of sharing your know how and opinions with millions of people on the entire planet - potentially, that is.

My name is Deniz and I’m part of the tech team at ENLYZE, a startup from Aachen looking to move to Cologne soon. We’re a passionate team of 10 engineers, physicists and designers working towards building the universal data layer for the manufacturing industry - but more on that later. For the past 18 months, we’ve been heads down in crunch mode. We’ve been rushing from one goal to another, not even stopping to take breath, let alone celebrating and acknowledging what technological hurdles we’ve faced and overcome so far.

That’s why I’ve decided it’s about time that we start our own blog focusing on our use of technology at ENLYZE. As an industrial IoT analytics startup, our stack spans from distributed constrained devices at our customer sites over stream analytics in the cloud to data visualization. This puts us in an interesting position, where we are confronted with challenges more often encountered in larger organizations working towards becoming a data driven company. Or as we like to joke:

We are doing big data without a dedicated big data team.

Working with these constraints and requirements, which admittedly sound more like an oxymoron than anything else has been and continues to be an exciting venture into modern day data engineering, forcing us to build simple, easy to use, yet powerful solutions maintainable by a selected few. And this story - to me at least - is undoubtably worth sharing.

As this is a tech blog, my aim for this very first post is to give you a high-level introduction to our system components so that after reading this, you can decide for yourself, whether keeping on reading it is worth your while. So let’s dive in!

What are we building at ENLYZE?

Oversimplified, our product can be described as a single streaming analytics pipeline from our customers’ shop floors into the cloud, where we clean, enrich and analyze the data and forward our insights back to the shop floor via our dashboard in near real-time. In turn, we can further break this view down into data capturing, real-time data processing and visualization, which we will touch briefly within the following paragraphs.

Capturing manufacturing data

On the shop floor level, our SPARK is the beating heart of our operation. Our software captures data from our voltage and current sensor, the FLUX, and also talks to NCs and PLCs of all major manufacturers. As an industrial analytics company, this gives us a major competetive edge, as we can model and optimize data formats for our use case and don’t have to rely on third-party contractors for data aggregation. The latter especially adds a considerable amount of complexity and cost, making any customer onboarding process a pain.

Real-time data processing

After capturing data, the SPARK sends the data to a streaming pipeline running on our cloud infrastructure. The primary job of this pipeline is to decompress, enrich and unify data coming in from multiple SPARKs for later use. From there, the pipeline branches off, sending data downstream to machine learning pipelines, while also storing it for later analysis and historical data visualizations. The machine learning pipelines produce insights and metrics about a specific customer asset, which reach from assessments of the machine-status to parameter-specific scores and recommendations.

Customer-facing visualization

The dashboard is the interface to our customers, consuming, condensing and visualizing raw machine data, metrics and alerts coming in from various sources of our systems. Currently, we’re also working on an analysis tool, which enables production plant managers to analyze their data in retrospective to find potential optimizations within production operations.

That’s it for now - if this spiked your interest, check out our other posts or add us to your RSS feed. If you have any suggestions, questions, feel free to shoot us a mail via hello[at]enlyze.com. And yes - we are hiring